Nevesbu presents paper ‘The effect of orthotropic steel on pressure hull collapse’ at Warship 2023 Conference in Bath, UK

Submarine design and build is a complex and challenging process that often requires years to refine and produce the desired vessels. In an age of increasing technological development tempo, the Warship 2023 conference will seek to explore mechanisms for delivering high-quality capabilities at pace. In particular, it will focus on availability and how to improve availability through design, life maintenance and consideration of crew availability and human factors constraints. On Thursday, 1 June, Nevesbu will present its paper ‘The effect of orthotropic steel on pressure hull collapse’.

In general pressure hulls are made of steel and this material is usually considered to be isotropic. Nevertheless, it is well-known that the properties in and perpendicular to the rolling direction will show a difference. Considering the complex stress state in ring-stiffened cylinders, orientation of the orthotropic material must have influence on the collapse pressure, but it is not easy to quantify.

Based on actual tensile tests in longitudinal and transverse direction of a plate nonlinear analyses are carried out to establish collapse pressures by means of the Hill plasticity model. The influence of isotropic behaviour is presented by rotation of the material over the geometry.

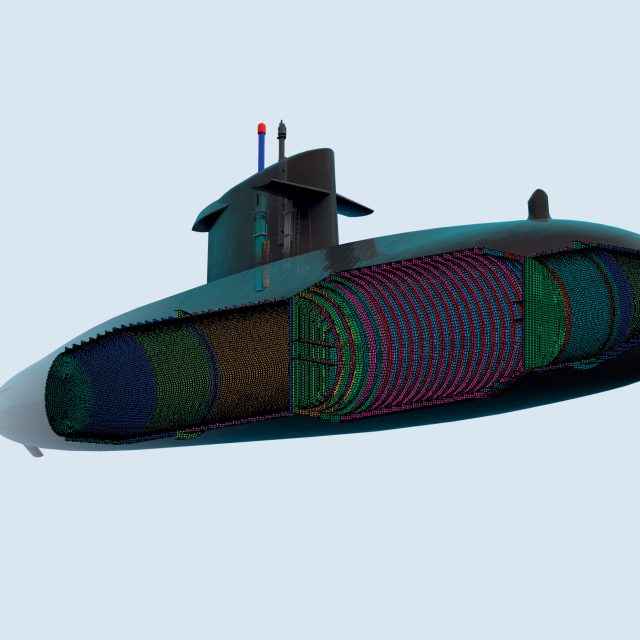

This study comprises material with a specified minimum yield stress of 355 MPa. In modern pressure hull design this material may be no longer applied but to demonstrate the effect of orthotropic behaviour the test results are applied to the Potvis class. This is a Dutch submarine design from the mid of the last century with a pressure hull made of St 52 like the material of the actual tests. The material model is rotated from hoop to axial direction, and the resulting collapse pressures are compared. The study reveals that for the material under consideration the orientation of the plate cannot be ignored. This means that it is imperative to consider material properties in perpendicular directions, and based on test results it must be decided how to manufacture the pressure hull.

Would you like to know more about the effect of orthotropic steel on pressure hull collapse? Albert will be pleased to tell you more.