A unique position in submarine engineering

Submarines are of indispensable strategic importance to many countries in providing security at and from the sea. They are deployed for vital missions, from gathering intelligence undercover to tracking down enemies and combating piracy and drug trafficking. The success of submarines depends largely on technology; every detail must be correct.

The Netherlands is about to make an important decision. In 2024, it is expected to be announced which supplier will build the new generation of submarines for the Ministry of Defence. This new generation of submarines will replace the current Walrus class, which has been in service since the late 1980s. Nevesbu contributed to the design of the Walrus class submarines in the 1970s and has been involved in every Dutch submarine project since. “We have contributed to every generation of Dutch submarines”, says Bart van Rijssen, Managing Director of Nevesbu. “As a result, we know the submarines inside and out, which appears to have been of great added value in the upkeep of the Walrus class. The naval shipyard regularly raises questions, and thanks to the knowledge we have accumulated over the past decades, we know exactly which specifications a solution must meet. Upkeep is part of our daily work.”

Expanding our submarine knowledge

The construction of the new fleet for the Dutch Ministry of Defence is a dot on the horizon. “We have unique knowledge that is of enormous added value for the realisation and upkeep of the new submarines”, says Bart. Over the past few years, Nevesbu has enhanced this specialist submarine knowledge by recruiting new, young and experienced people who have mainly worked on submarines. This includes innovative studies, such as the concept design of an all-electric submarine. Colleagues have also gained experience during projects, and master classes in submarine design have been organised to learn all the principles of submarine design. “Submarine technology is a niche market. Maintaining and expanding our knowledge in this area and preparing our employees for the new submarines has been a key focus in recent years. But also to be able to say: ‘In the Netherlands, Nevesbu is the expert when it comes to submarines.’ I’m convinced of that.”

This in-depth knowledge comes from decades of experience. Since it was established in 1935, Nevesbu has worked continuously on submarines for the Dutch and foreign navies. In addition to the upkeep programme for the Walrus class, Nevesbu currently works on the construction, upkeep and modification of submarines in four other countries. But what exactly does this specific knowledge entail, and how do we apply it within projects?

Three areas of expertise

When it comes to the design and integration of submarines, the expertise at Nevesbu can be divided into three areas: new construction, upkeep and modification. Nevesbu is also regularly approached by various other countries seeking advice on seaworthiness. Bart: “We provide advice to countries that are considering buying new submarines or modifying existing vessels, and we help them evaluate the proposed designs. I think it’s a great compliment to Nevesbu that we have this authority. It says something about how we are perceived in the business.”

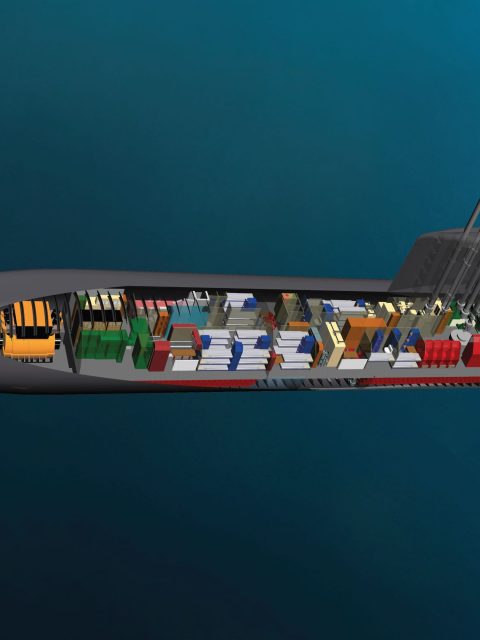

A submarine’s most important design requirement is that everything must be balanced. More so than with other types of vessels. The balance of heat, energy and space has to be perfect. “It’s very precise”, Bart acknowledges. “It’s up to us to judge whether this balance truly exists. It’s very interesting work.”

Complex engineering

This balance must also be maintained in terms of engineering. It is very complex because a submarine has at least half a million components. By comparison, a passenger aircraft has around 100,000 components. “If you need to gain some space somewhere, it is always at the expense of something else. Changing one element, however small, has a domino effect on the design of a submarine. Every detail must be correct. And all that in a space that is 100 percent utilised. Not a single centimetre of design space left over.”

This extreme balance is a direct reflection of the complexity of modifying submarines. Changing anything on a submarine immediately affects the entire design. “For example, if you need to replace a periscope, it will not be exactly the same size and weight as the one you are replacing. So, the whole vessel must be continuously examined when making a modification.”

Undetectable

The key question is: why is the design or the implementation of modifications to a submarine so precise? The answer is simple: a submarine must be silent. “That is one of the most important requirements: it must be undetectable. Otherwise, it cannot do its job”, Bart continues. “Everything has to be silent. That means high demands are placed on the equipment and its integration. It must not emit any noise, it must be shock-proof, and the skin of the submarine must not be in direct contact with the equipment; otherwise, it will also emit noise.” Submarines are designed to operate unassisted for long periods because otherwise, they would be detectable. The design incorporates redundancy, meaning that system B will take over if system A fails. Even if a submarine suffers severe damage during a mission, it can still remain undetected. The equipment and a submarine’s shape and materials play a vital role in avoiding detection. A submarine must be able to move as smoothly and quietly as possible underwater so that it emits as little noise as possible, reflects as little sound as possible and cannot be located by sonar equipment.

Continuous knowledge development

Together with a knowledge institute and industry partners, Nevesbu is conducting development work in the field of echo target strength in submarines. The R&D programme is aimed at what is known as ‘echo target strength reduction’: mitigating sound reflection (echo) when sonar is used to locate a submarine. “These are big steps we are taking”, says Bart. “It’s about the coverings and use of materials on submarines. In this R&D programme, we are working with partners to develop and integrate materials that ensure sound is absorbed and not reflected in the same direction.” Nevesbu has been involved in this programme for years and, with a large group of specialists, has plenty to do for the coming years. “The holy grail is for a submarine to be completely silent and untraceable. This will never be entirely possible because a submarine needs machines and pumps to operate. But we can get as close as we can. With this programme, we are investigating how. The knowledge gained and shared is particularly valuable for Nevesbu and the other participating parties – knowledge development, thus.”

Seaworthiness

Overall, the expertise and intensive accumulation of knowledge (e.g., in cooperation with knowledge institutes) ensure Nevesbu maintains its unique position in the field of submarine technology in the Netherlands. For example, Nevesbu has been asked by the Seaworthiness Authority (part of the Ministry of Defence) to provide support in resolving issues relating to the seaworthiness of submarines. Bart: “It says a lot about us that we are asked to advise on this. We want to continue to fulfil this role with the new fleet. When a question is raised, we can answer it because we have this niche knowledge. We want and need to be the knowledge experts in this field.”

It will become more apparent next year which supplier will have the honour of building the new generation of submarines. Bart is confident that Nevesbu will have a role to play, following in the footsteps of the Walrus class. “In addition to designs, we provide the necessary expertise to upkeep and modify a reliable and advanced fleet, which is also good for the Netherlands.” Nevesbu hopes that the next stage of the project will soon be reached. That’ll be good for the Navy and the industry. Nevesbu is ready!

Would you like to know more about Nevesbu's submarine expertise? Albert will be pleased to tell you more!